MRT

sMRT Shield

Personal Locator Beacon

for optimal safety at sea

MRT (Marine Rescue Technologies) partnered with IDC to develop their sMRT Shield personal locator beacon from initial research and concept generation to detailed design for manufacture, prototyping and production support.

Robustness and reliability in the most rugged of environments

As leaders in ‘man overboard’ solutions for offshore and recreational use, MRT was keen to launch a new range of location beacons which provided distress transmission anywhere in the world. They came to IDC to help develop a ground-breaking new device which would automatically deploy an antenna in a water emergency, to maximise transmission across three different communication platforms. The product also needed to be capable of use on land to be a truly global location beacon.

A solution for land and water

A two stage process for arming and activating the device was developed to avoid accidental transmission. The team was keen to simplify this process so activation could be made quickly with just one hand. Using insight from the usability studies, a solution was developed for a dry land emergency where the user swiped a slider horizontally and down to arm the device - this released the antenna manually, and the device was then activated by pressing a button for one second.

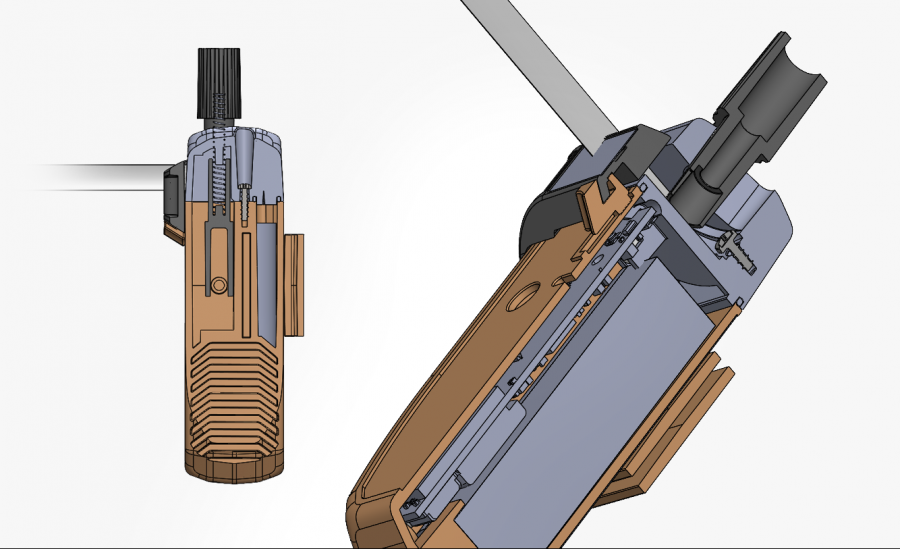

In a ‘man overboard’ situation, the device needed to automatically deploy the antenna. IDC’s usability studies demonstrated where the antenna would need to be positioned for best transmission when mounted. The device differed from the land version by including an activation tab, attached by a cord to the life jacket, which when inflated pulled on the tab to release the antenna. IDC’s engineers developed the automatic antenna deployment mechanism. A flexible metal antenna was wound up in a spring mechanism, which was triggered to unwind and deploy vertically when the activation tab was pulled during life jacket inflation.

Robust engineering with a fresh visual brand language

The materials had to withstand a range of temperatures and pressures. PC-ABS was selected for the main body of the unit, with the outer slider components for arming the device made from POM with its low friction, high wear resistance and dimensional stability. The team developed it to IP68 Rating. Numerous prototypes were developed and assessed for pressure, drop testing, and water resistance until the team was satisfied with seal strength and robustness. The visual language communicated a practical design and honours the requirements of its users. The activation button was made large and clear with a tactile membrane key pad used on the front. User direction images were added to the front of the device as an extra visual aid for operation on land. IDC’s team considered Design for Manufacture (DFM) throughout the development, applying tolerance stack analysis to ensure all components worked effectively in the final assembly.

Our involvement in the development of sMRT Shield:

- Usability analysis

- Competitor analysis

- Industrial design

- Mechanical engineering

- Full CAD design for manufacture

- User testing and Ergonomics

- Prototyping

- Tolerance stack analysis

- Performance testing

- Materials specification

- Tooling management and production support

Sign up to receive our top resources on product development and innovation.