VOLVO

Excavator Cab Interior

Attractive and ergonomic

robust and cost effective

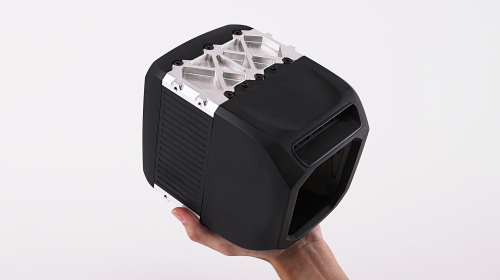

Creating an attractive, ergonomic and durable cab environment, with cost effective rotational moulded parts, IDC developed all design for manufacturing detail, including ventilation ducting and housing for instruments and controls. IDC Models made all the mould patterns.

IDC was tasked by Volvo to take a styling concept of the dashboard and interior compartments and develop 3D models and engineering CAD data to enable the components to fit to the existing cab superstructure, and to develop the parts to be suitable for rotational moulding production.

IDC took Volvo’s initial cab interior design, updated and rationalised the design to create component parts specific to a rotational moulding process. Included in the development was an update of the production line process to assemble each part into the cabin. Liaison and developments were with Volvo staff in both Sweden and France

IDC refined the design aesthetic of the cab interior, integrating well-engineered rotational moulded parts into the cab superstructure. Following the development programme IDC produced full size production patterns in house, using our CNC machining facilities and the pattern making skills of our model making team.