Baxter

CAPD+

Continuous Ambulatory

Peritoneal Dialysis

IDC helped Baxter develop a safer CAPD device, packed with beneficial features to simplify dialysis at home.

A global leader in the treatment of kidney disease

CAPD is a type of peritoneal dialysis that uses gravity, rather than a machine, to exchange waste dialysis solution for fresh solution (known as dialysate) after filtering across the peritoneum of the abdomen. This can take place up to five times a day, lasting up to 45 mins each session. Baxter wanted to develop a device that was more efficient, hygienic and easier for patients to use, as well as being more aesthetically pleasing for use in patients’ own homes.

Understanding patient needs

IDC’s team conducted user research to understand how patients were using existing CAPD devices in their lives, to identify pain points and where improvements could be made. Patients were interviewed and the team identified a number of issues.

The setup of most patients was found to be basic with dialysate bags just hooked onto stands, with no provision for effective positioning or patient comfort. Patients were also putting equipment on the floor to be within easy reach, including microwaves for warming up dialysate bags - highlighting issues of cleanliness and the risk of infection. One of the biggest concerns voiced by patients was knowing if all the waste dialysate had drained out properly, since there was no exact way of measuring. This was particularly important as failure to extract it could mean risking infection and toxicity from waste products.

Another beneficial design feature was a pre-warming drawer to bring the fresh dialysate to body temperature. This was a great innovation for patients as they could simply programme the system to warm the dialysate for a certain time so it was ready for dialysis. The warming drawer was a key part of the development and many concepts were explored and tested with users to find the best way of heating the dialysate. A full heating plate sitting in contact with the bag was found to be the best solution to gently warm the liquid without risking hot spots.

Ergonomic design and waste dialysate weighing platform

IDC’s designers worked to get the right balance between a medical device and a sleek piece of furniture for the patient’s home by considering materials and style. Ergonomics was an important part of the project with the device designed with a stable base and angled to the optimum position for the drainage tube to extract waste dialysate comfortably from the patient. In addition, this bag was positioned on a weighing platform which informed the patient when the drainage process was complete, allaying patients’ concerns about accidentally retaining some of the waste dialysate.

Manufacturing considerations

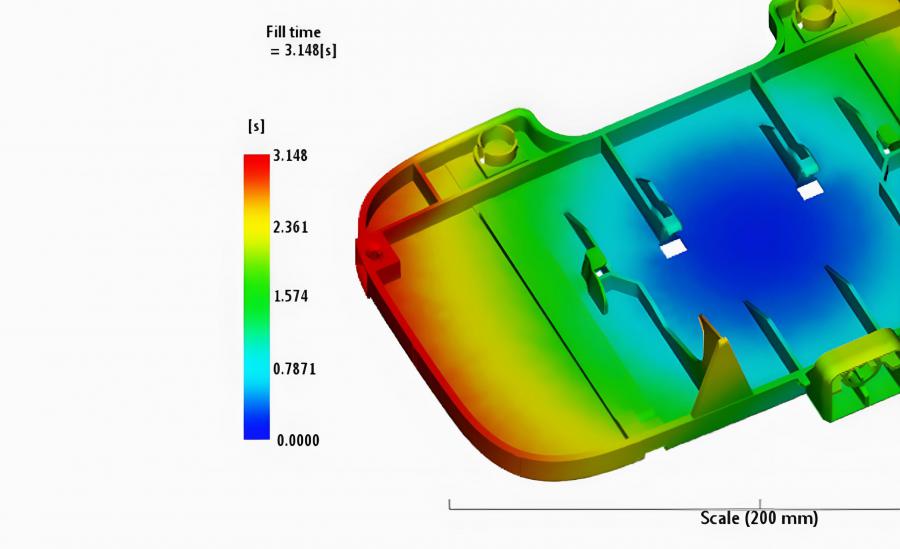

Design for manufacture (DFM) was considered throughout the development, with the aim of making the product as high quality and cost effective as possible in production. IDC’s team did this by building the device around a spine made of an anodised aluminium extrusion from which other plastic components attached. Mould flow analysis and tolerance stack analysis were used to ensure the highest levels of quality.

Towards the end of the project, the team conducted a further usability study using a final working prototype of the device. Patient feedback was excellent, and IDC is delighted to have supported Baxter in their next stage of development for products to treat kidney disease.

Our involvement in developing the CAPD+ device for Baxter:

- User research

- Competitor analysis

- Industrial design

- Mechanical engineering

- CAD design for manufacture

- User testing & Ergonomics

- Prototyping

- Tolerance stack analysis

- Performance testing

- Medical documentation

- Materials specification

- Tooling liaison