Forty Years In The Making

Forty Years in the Making

Industrial Design Consultancy (IDC) has just celebrated its 40th year of business. IDC’s founder and chairman, Mike Woodhall, speaks about the fascinating history behind the company and design trends as it has moved from age to age. Looking to the future, IDC’s MD, Stephen Knowles, discusses where the industry is heading and what he believes are the key opportunities and challenges for the future.

1972. Three years a"er the BBC begins broadcasting in colour, big boxy colour televisions are starting to appear across the country. The Volkswagen Beetle is the most popular car ever sold and Atari launches the first video game to achieve commercial success. Digital watches are introduced this year and the first scientific hand-held calculator is available at an astronomical price. This is the year that it all started for IDC.

In 1972, working as Head of Audio Design for GEC, Mike Woodhall was busy supporting the expansion of the brown goods market to meet the demand for colour televisions and audio equipment. This role meant that he was constantly making new contacts and he was soon approached by an American company, Datacard, which asked if he would consider working for them as an industrial designer for two days a week. Accepting this role, he was offered a perfect opportunity to set up a company; freeing up another three days a week for other projects. These projects soon turned full-time and Industrial Design Consultancy was born.

Initially, IDC operated out of Mike Woodhall’s home in Maidenhead, where he had set up a studio. As the contracts continued to roll in, more staff were required and space became an issue.

Mike explains, “These were the times when designs were drawn by hand. Concepts were created by pen and pencil on paper using A0 drawing boards, and plan chests of a similar size were used for storage. The design cycle was much slower and space was at a premium. The model making process also had similar constraints; what can be made in a matter of hours now by rapid prototyping and the use of CNC could take weeks to handcra", and this process also demanded considerably more space than today.”

The need for space brought about IDC’s move to Datchet. The company initially worked from two houses with a commercial entrance on Datchet High Street. One building was converted into a design studio and the other, located over the street, was used as a workshop for model making. During this time, IDC was operating as three separate businesses, with specialisms in product design, graphic design for signage, and electronics for the reading of bar codes for companies such as Woolworths, BHS, Top Shop and BT. In these early years, the team took on many different projects and soon each business area was building its own reputation following the successful outcome of each project. Clients were repeatedly coming back with new work, but Mike Woodhall was conscious that each business was growing independently and he wanted to maintain focus. A decision was made to concentrate on the product design business and the graphic design and electronics businesses were closed. At this point IDC took on a similar structure to the company of today, with IDC for industrial design and engineering and its separate model making division, IDC Models.

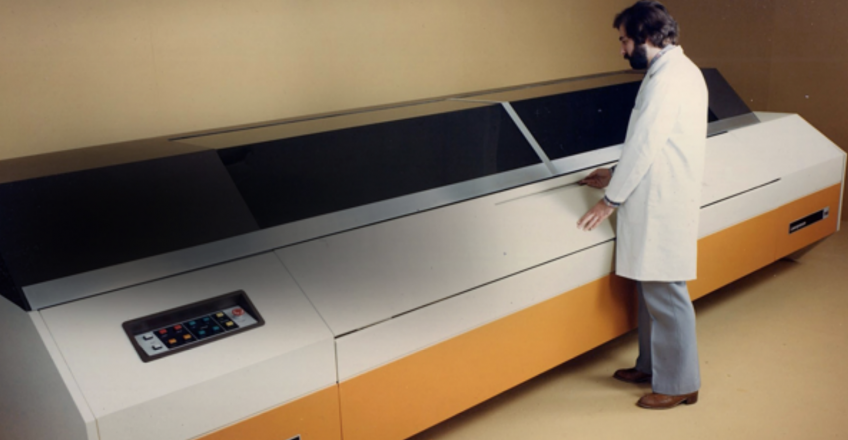

At first, IDC’s core business was a mix of domestic appliances such as irons, kettles and cookers, but the technology soon shi"ed to computer control equipment. IDC’s landmark project came a few years into the company in 1975, when it produced the industrial design concept for a Crosfield 550 Scanner. This was a high value scanner that was almost revolutionary in the print industry, long before the time when Apple Macs and PCs were able to handle imaging. It was the world’s first computer controlled digital scanner with the colour separation and correction process both performed by the computer. The success of this project earned IDC its first award 3 and the company went on to handle other high profile projects with a technological bias, such as money dispensing and sorting machines for De la Rue and credit card machines for Rapid Data, as well as an international project to develop a lottery ticket machine to be used by the French lottery. IDC then went on to earn a second design award (from the American Electronic Association) for designing a PCB printer for DEK.

Mike Woodhall believes his team had the ideal skills for the design industry at that time; “Technology was taking off and we had a great team of designers, engineers and electronics specialists. Together we were able to simplify complex problems and use our experience to engineer unique solutions. We were also very adept at designing around patents and coming up with new concepts of our own or for clients. This is still a key part of IDC’s success today.”

IDC also established strong links with suppliers abroad. The team had particularly strong contacts with toolmakers in Portugal, which at the time had the best facilities in Europe. Good relationships with toolmakers and moulding contractors also brought new business through recommendation and soon IDC’s business grew to a 60-strong team. In 1985, to accommodate 5 IDC’s growing business, the company moved to its current site in Datchet, with studio, offices and modelling workshop all under one roof.

There were teething problems with this new technology though, as Mike Woodhall recalls, “At the time, the so"ware developers were all fighting to dominate the market and product designers o"en ran into issues of so"ware compatibility. Projects ran smoothly as long as everyone used the same so"ware, but inevitably there were occasions when this wasn’t the case and then the technology was quite an obstacle. To overcome these problems IDC used three or four different so"ware systems, to ensure we could always fit in with clients.”

Since IDC’s launch in 1972 Mike Woodhall believes there has been a distinct pattern to IDC’s projects, “The company has seen waves of different design trends, influenced both by technology and the economy. The 70s brought many domestic projects, despite economic difficulties as new technologies were developing and products could be mass-marketed. IDC was fortunate to have a team with the right expertise throughout the 80s as computers were taking off and products were becoming influenced by electronics. This is when IDC really started to gain momentum and by the 90s we had an excellent reputation for combining design appeal with leading edge technology.”

Perhaps one of the strongest qualities of IDC today is its ability to design products for a sustainable future. In 2008, the company employed a dedicated sustainable design expert, who implemented a new system to build sustainability into the design process. This system was so successful that IDC used it as a basis to develop its own so"ware product, the LCA (Lifecycle Assessment) Calculator, for analysing sustainability at all stages of design, which it now sells to customers. This so"ware is being used by all types of organisations, from big automotive companies such as Jaguar Land Rover to small design consultancies and academic institutions.

Identifying potential opportunities and threats has always been important to IDC and as part of IDC’s 40th anniversary celebrations it organised a special workshop for clients to come together and discuss what they believe to be the key opportunities and challenges for their products in the future. The outcome was fascinating, with issues of globalisation rating highly as both an opportunity and a concern; with higher customer demands and product expectations globally; issues of copycat technology (several clients having already experienced this); issues of product usage affecting reliability when used in countries without high training standards; regional supply and support; as well as other general issues such as meeting international legislation and 10 quality standards. Clients also felt that transfer to manufacturing was a significant challenge for them, with a wide variety of issues cropping up when production starts. This is an area that IDC had previously identified as being a concern and now offers a range of ‘design to production‘ services to support clients.

This article was written shortly before the death of Mike Woodhall (on June 8th 2013), who was previously Chairman of IDC.